|

Emulsification |

|

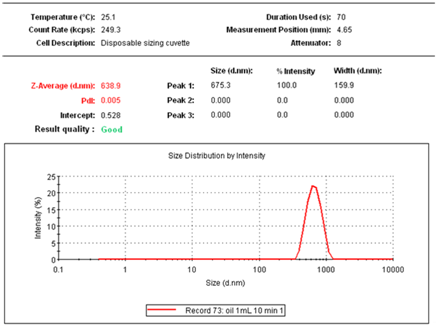

SoniMixer's unique BCA technology enhances the emulsification efficiency of the sample and achieves rapid emulsification without the need of additional chemical emulsifiers (see the left picture above). The SoniMixer emulsification test showed that the average particle size of the oil droplets processed by the BCA technique for 10 minutes was 638.9 nm (shown on the right picture). In addition, the sample was kept at room temperature for more than 6 months without demulsification. The result indicates that the emulsification is stable and can be applied to different fields such as food, beauty care products, etc. |

|

Emulsification is the effect of a liquid being uniformly dispersed in another liquid that is immiscible with very small droplets. The one in which the droplets are formed is called the dispersed phase; the other phase that is connected in one piece is called the continuous phase. SoniMixer's BCA technology breaks up oil droplets into fine particles with high-energy ultrasonic vibration, and at the same time, with continuous and stable rotary stirring, the particles are evenly dispersed into the continuous phase to form a stable emulsion. |

|

Applications |

|

Before After |

|

©COPYRIGHTS 2012. ALL RIGHTS RESERVED. JetPump Technology Inc. |